Pharmaceutical Water Storage and Distribution Systems

PW and WFI storage and distribution systems.

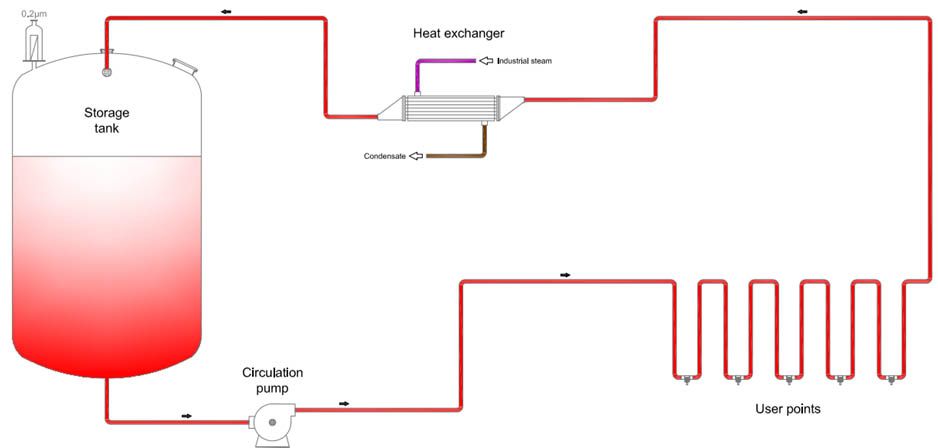

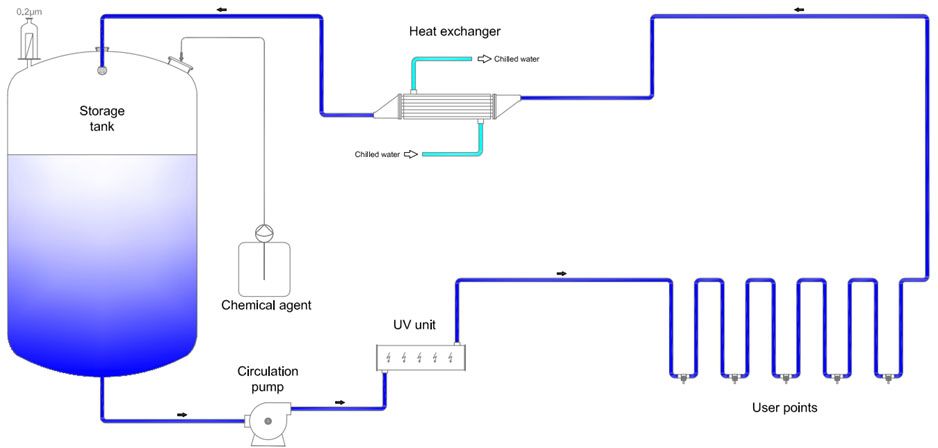

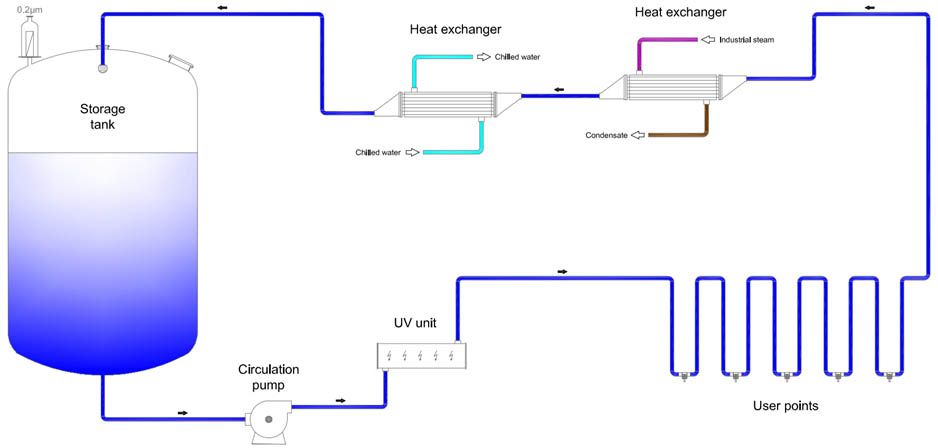

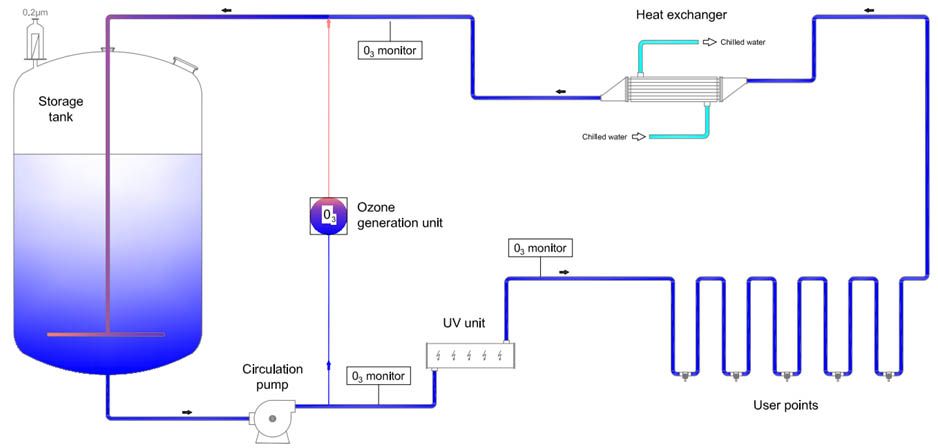

The pharmaceutical water distribution system is usually organized in form of a circulation loop, assuring turbulent water motion in the pipes 24 hours a day and 7 days a week. In case of Purified Water, most often, the loop works in a cold mode, at temperature in the range of 15 - 25 °C. WFI water is usually stored hot, at temperature > 80 °C.

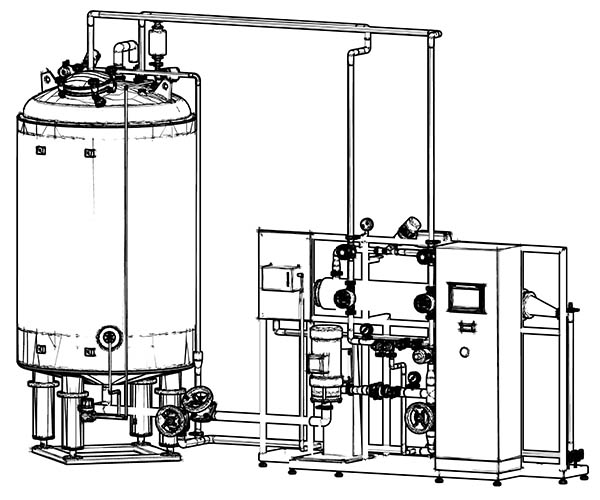

The main elements of the water distribution system are a storage tank and a circulation pump or pumps. The task of the storage tank is to compensate the peaks in water use. Circulation pumps are responsible for ensuring turbulent flow in pipelines and maintain the required pressure in the system. Depending on the number and location of consumption points, the distribution system may contain one or more circulation loops starting and ending in the storage tank.

Very often, UV units for water disinfection devices are installed at the PW loop feed lines to minimize the risk of bacterial growth in the system. UV disinfection devices that are installed in water distribution systems for the pharmaceutical industry must be free from dead-legs and completely drainable.

In PW cold water loops, it is necessary to install a heat exchanger, which protects against excessive temperature increase in the system due to energy from the pump transferred to the water as a result of frictions on the pipe walls in effect of constant circulation. Water distribution systems for the pharmaceutical industry use shell-and-tube heat exchangers of a special hygienic design, so-called DTS (Double Tube Sheet) type heat exchangers.

The PW storage and distribution system must undergo periodically sanitization. Automatic sanitation process is recommended. There are three main methods to sanitize purified water storage and distribution systems:

1) Chemical sanitization:

2) Thermal sanitization:

3) Sanitization with ozone:

Water for injection storage and distribution systems should be periodically sterilized at the temperature of ≥ 121 ° C. The WFI storage and distribution systems may be sterilized using superheated water or pure steam.