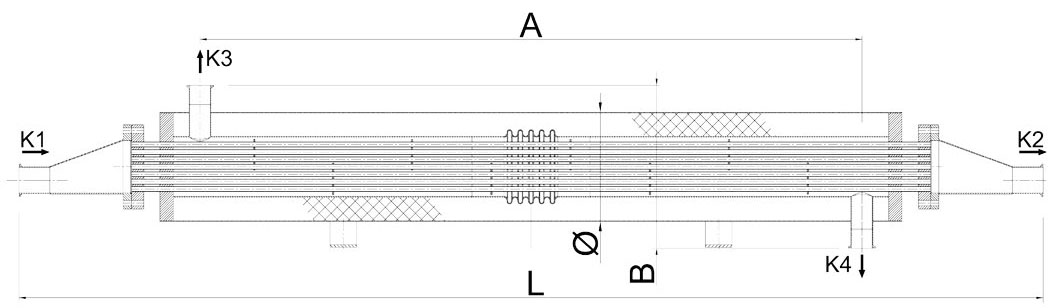

Sanitary Heat Exchangers

Our company manufactures sanitary heat exchangers (DTS = Double Tube Sheet) for pharmaceutical and cosmetic industries.

- All clean media wetted parts are made of stainless steel AISI 316L.

- Internal roughness in standard execution Ra<0.8µm. Better surface quality (0.6 µм, 0.4 µм) as well as electropolishing are available on request.

- Not wetted parts made of stainless steel AISI 304.

- Double wall bottoms assure full separation of clean media section from heating/cooling agent.

- Aseptic flanges DIN 11864-2.

- Tri-Clamp clean media connections.

- Flanged heating/cooling media connections.

- Maximal working pressure: 10 bar in pipes, 6 or 10 bar in shell.

- Maximal working temperature: 160 °С.

- Heat exchangers are supplied with mineral wool thermal insulation in stainless steel cover.

The following standard set of documentation is delivered along with each exchanger:

- Declaration of conformity.

- 3.1 material certificates for all clean media wetted parts.

- Copies of welders’ licenses.

- Welding gas specification.

- Pressure test report.

- Cleaning & passivation report.

- Assembly drawing.

| Type | SHE-10 | SHE-15 | SHE-25 |

| Heat exchange surface (m2) | 1.0 | 1.5 | 2.5 |

|

Maximal operating pressure: shell (bar) pipes (bar) |

7.5 12.5 |

||

| Maximal operating temperature | 160 | ||

| Material of wetted parts | AISI 316L | ||

| Roughness of wetted parts | Ra < 0,8 μm (better finish available on demand) |

||

| Hydraulic connections Tri-Clamp DN | 40 | 50 | 65 |

|

Dimensions: internal diameter Ø mm total length, ca. L mm distance between connectors, ca. A mm distance inlet/outlet, ca. B mm |

204 2000 1234 304 |

204 2500 1734 304 |

254 2550 1726 350 |